Discover unmatched productivity with our Polyurethane Sandwich Panel Machine. Featuring state‑of‑the‑art automation and precision control, it guarantees consistent quality, energy efficiency, and robust performance for premium PU products.

Polyurethane Sandwich Panel Machine

Our Polyurethane Sandwich Panel Machine represents the pinnacle of modern manufacturing technology, specifically engineered for efficiency, precision, and adaptability in producing high-quality polyurethane products. At the heart of the system lies a state‑of‑the‑art automation platform, seamlessly integrated with advanced control systems to ensure that every stage of the production process meets the highest quality standards. This robust automation minimizes human error and significantly enhances production speed, resulting in a consistent output that meets the rigorous demands of today’s competitive markets.

Designed with energy efficiency in mind, the production line incorporates innovative technologies that optimize resource consumption without compromising performance. By reducing energy usage and operational costs, our system not only supports sustainable manufacturing practices but also delivers a rapid return on investment. Precision control capabilities allow for fine‑tuning of production parameters, ensuring that each batch of PU products achieves uniform density, strength, and durability.

Flexibility is another hallmark of our PU production line. It is capable of adapting to various production volumes and product specifications, making it an ideal solution for businesses seeking to scale operations or customize their product range. Comprehensive after‑sales support and expert maintenance services further ensure that the production line operates at peak efficiency, minimizing downtime and prolonging the equipment’s lifespan.

In summary, our Polyurethane Sandwich Panel Machine is a robust, energy‑efficient, and highly adaptable solution designed to meet the evolving needs of modern manufacturing. With advanced automation, precise control, and sustainable design, it provides a competitive edge in the production of premium polyurethane products, making it the preferred choice for industries around the globe.

Our commitment to excellence goes beyond technology. We invest in ongoing research and development, ensuring our PU production line evolves with industry trends and advancements. This forward‑thinking approach guarantees that your production capabilities remain cutting edge, delivering performance and quality year after year.

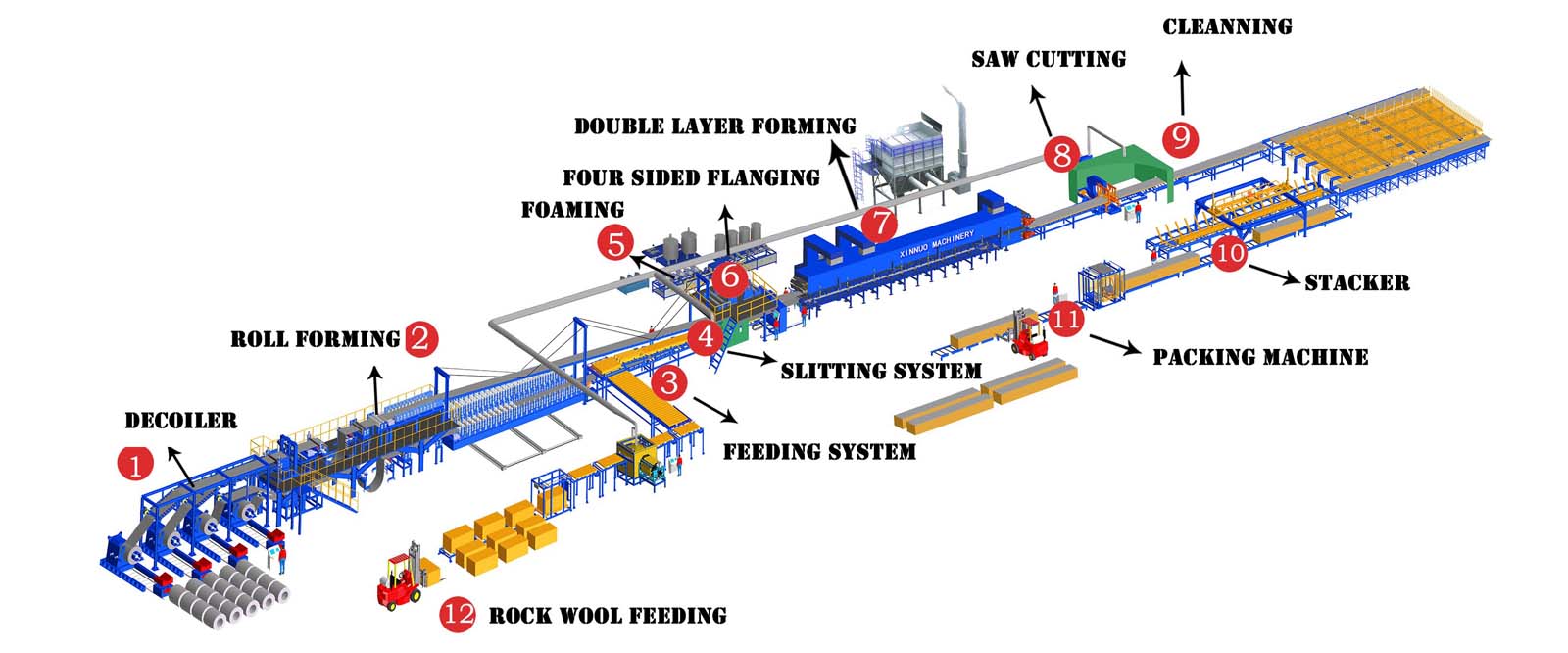

| NO | ||

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000&1200mm |

| 3 | Rollers | 17-44rows |

| 4 | Dimensions | 38.0*2.25*2.5m |

| 5 | Power | 30kw |

| 6 | Thickness of the plate | 0.3-0.8mm |

| 7 | Productivity | 2-6m/min |

| 8 | Diameter of the roller | Φ90mm |

| 9 | Weight | About 15 T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Material of the cutting plate | Cr12 |

| 12 | Processing precision | Within 1.00mm |

| 13 | Control system | PLC control |